3015 / 4020 / 6020

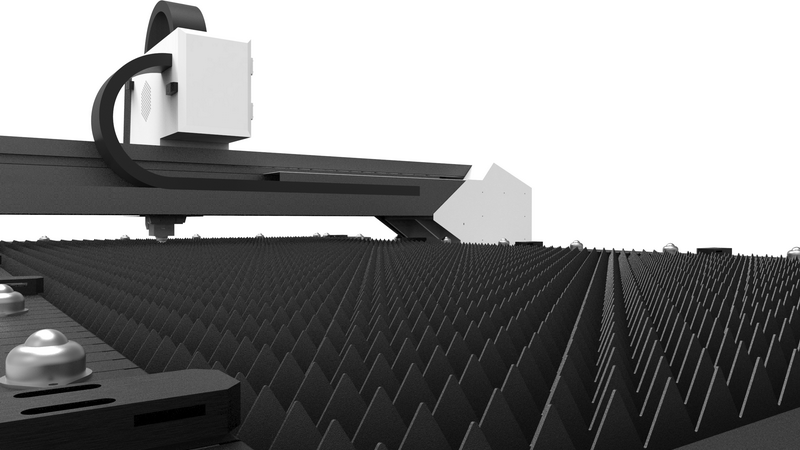

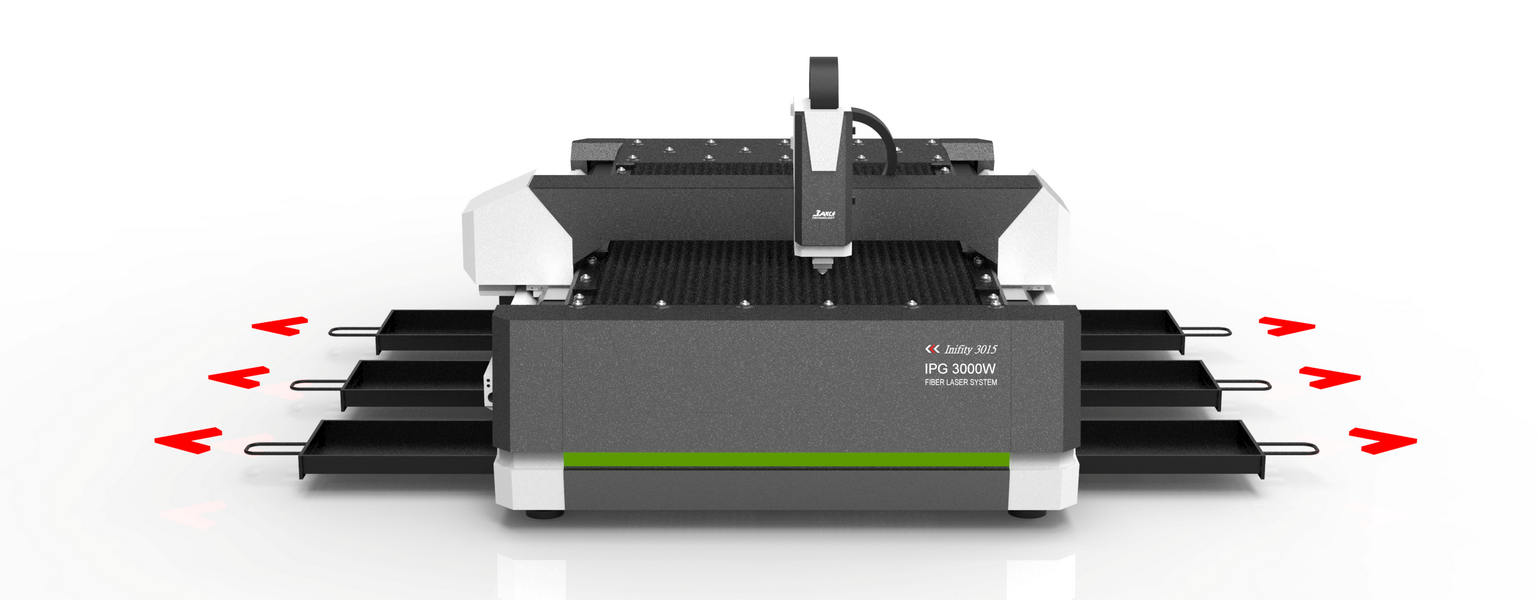

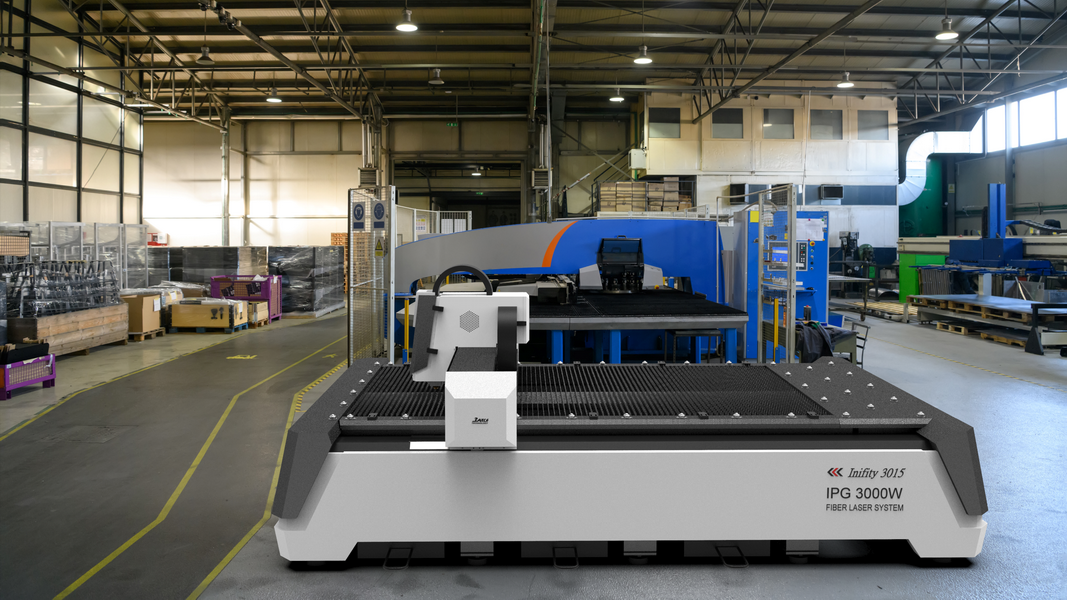

■ Open-type + Single Platform, suitable for general cutting applications.

■ Processing Sizes: 30001500mm / 40002000mm / 6000*2000mm (optional)

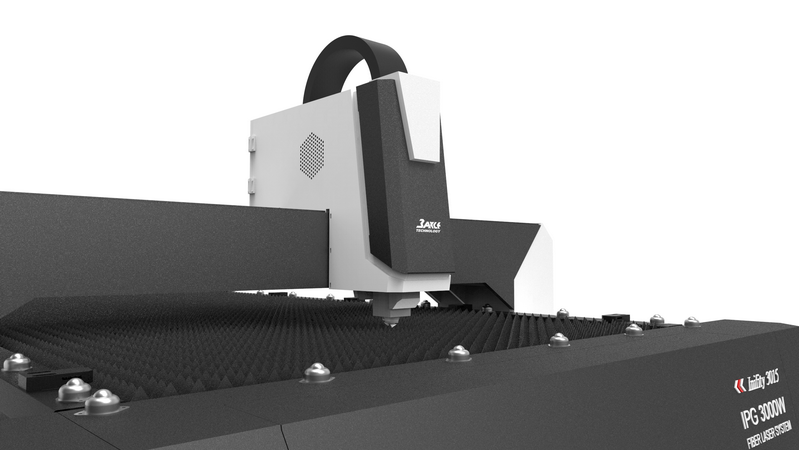

■ Laser Power: 1500W / 2000W / 3000W / 6000W

■ Laser Brand: IPG Laser (standard) / nLight / Raycus

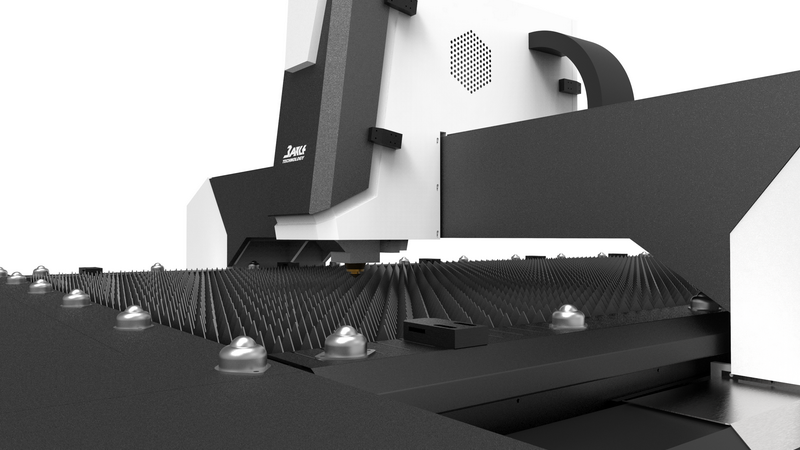

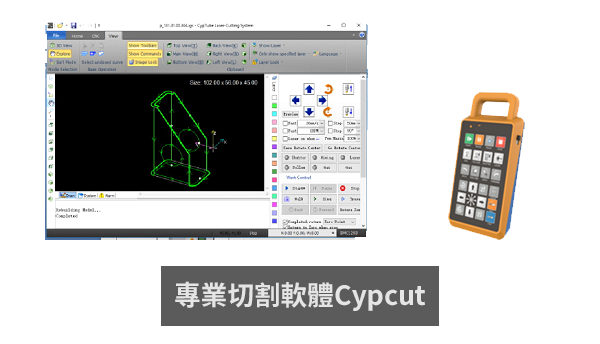

■ Applicable Materials: Aluminum, Stainless Steel, Galvanized Sheet, Carbon Steel, Silicon Steel, Brass, Copper, and other thin metals.

■ Consultation Hotlines: Mr. Hung at 0965-236-169