Especially for filter systems that produce oil/gas/oily objects

■ It is recommended for users who need large suction airflow and fiber laser metal cutting machine.

■ High-horsepower exhaust air, effectively filtering metal cutting oil and gas

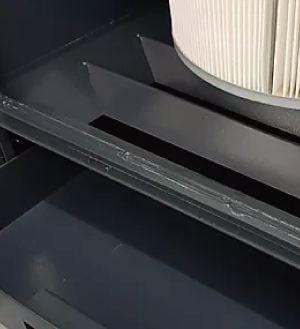

■ Water- and oil-proof filter elements from major Japanese manufacturers.

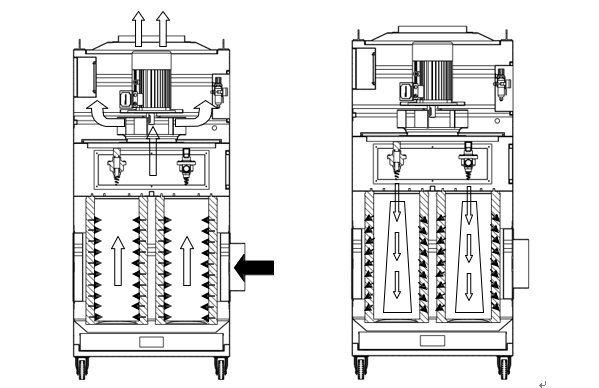

■ Automatic pulse back-blowing and dust removal.

■ The filtration efficiency of dust above 0.3μm is more than 99%.

■ Consultation Hotline: 0965-236169 Mr. Hung

■ One year warranty service

■ Taiwanese technicians