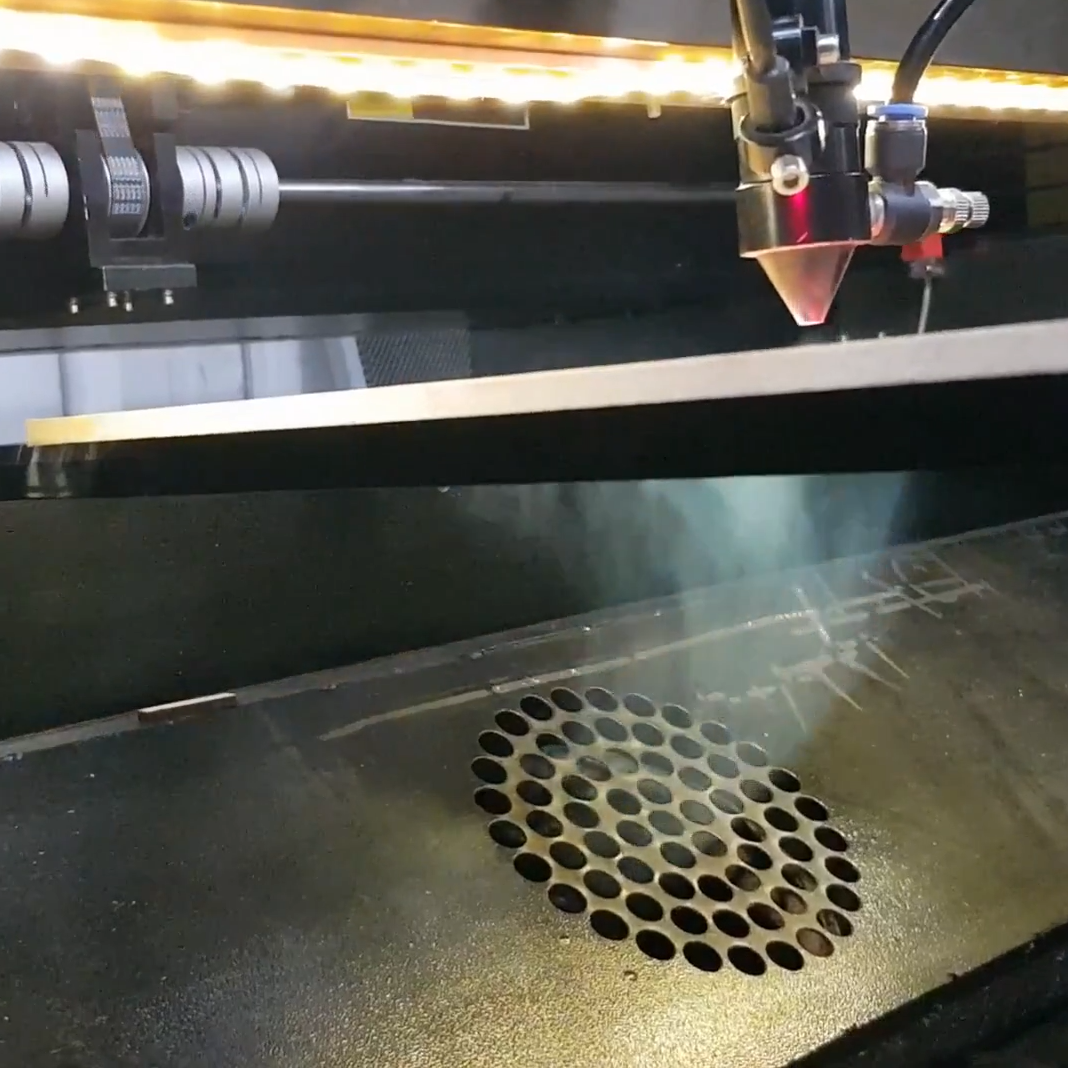

Many industrial productions will form toxic and harmful dust and smoke. Simply put, any material that is cut, engraved or physically changed in any way during all operations will produce harmful substances. To

►Laser (cutting, engraving, marking, welding, cladding, etc.)

►Hand and machine welding

►Food and pharmaceutical tobacco production packaging

►Advertising production, printing and inkjet

►Laboratory, beauty and medical

►Odor filter for reflow soldering equipment

►Odor filter for injection molding machine

►LCD monitor

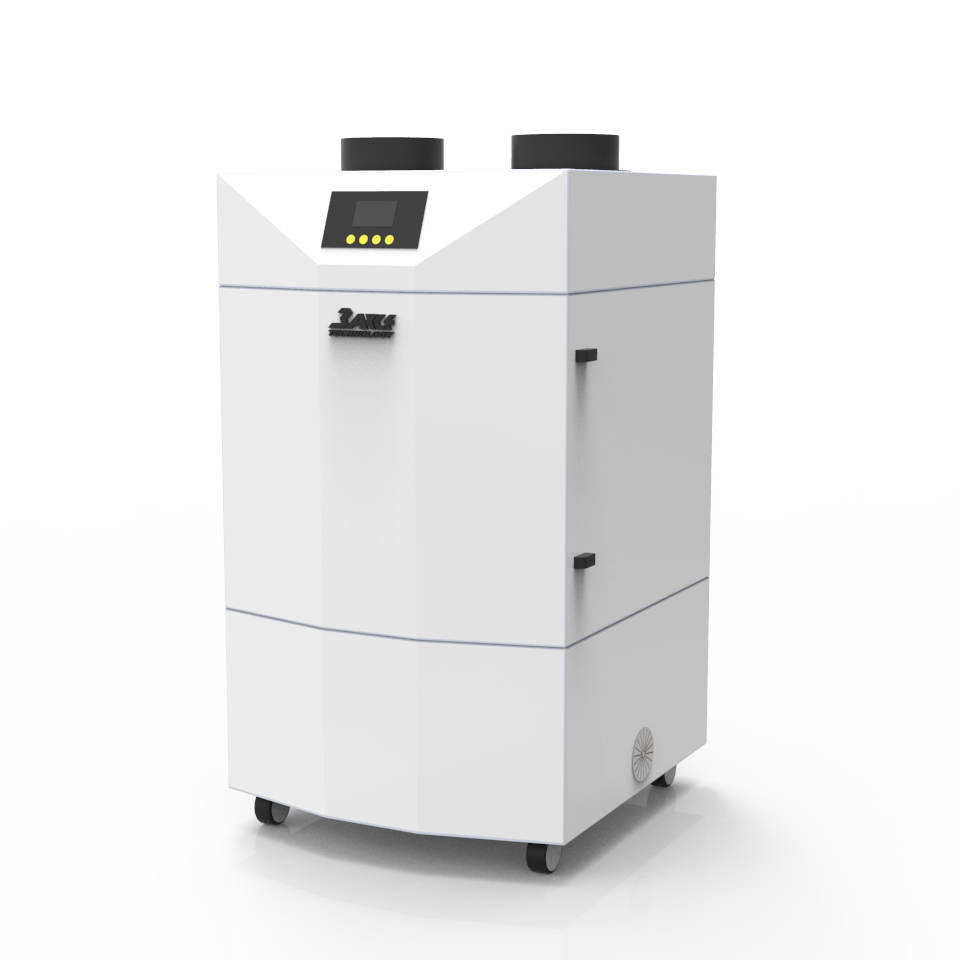

►10 speed adjustable

►Real-time display status display

►Wireless remote control: remote switch/air volume adjustment/timed shutdown

►Built-in two-stage filter blockage warning sound to remind the filter material to be replaced and replaced immediately.

► Purify the pungent smell volatilized by automated mass production

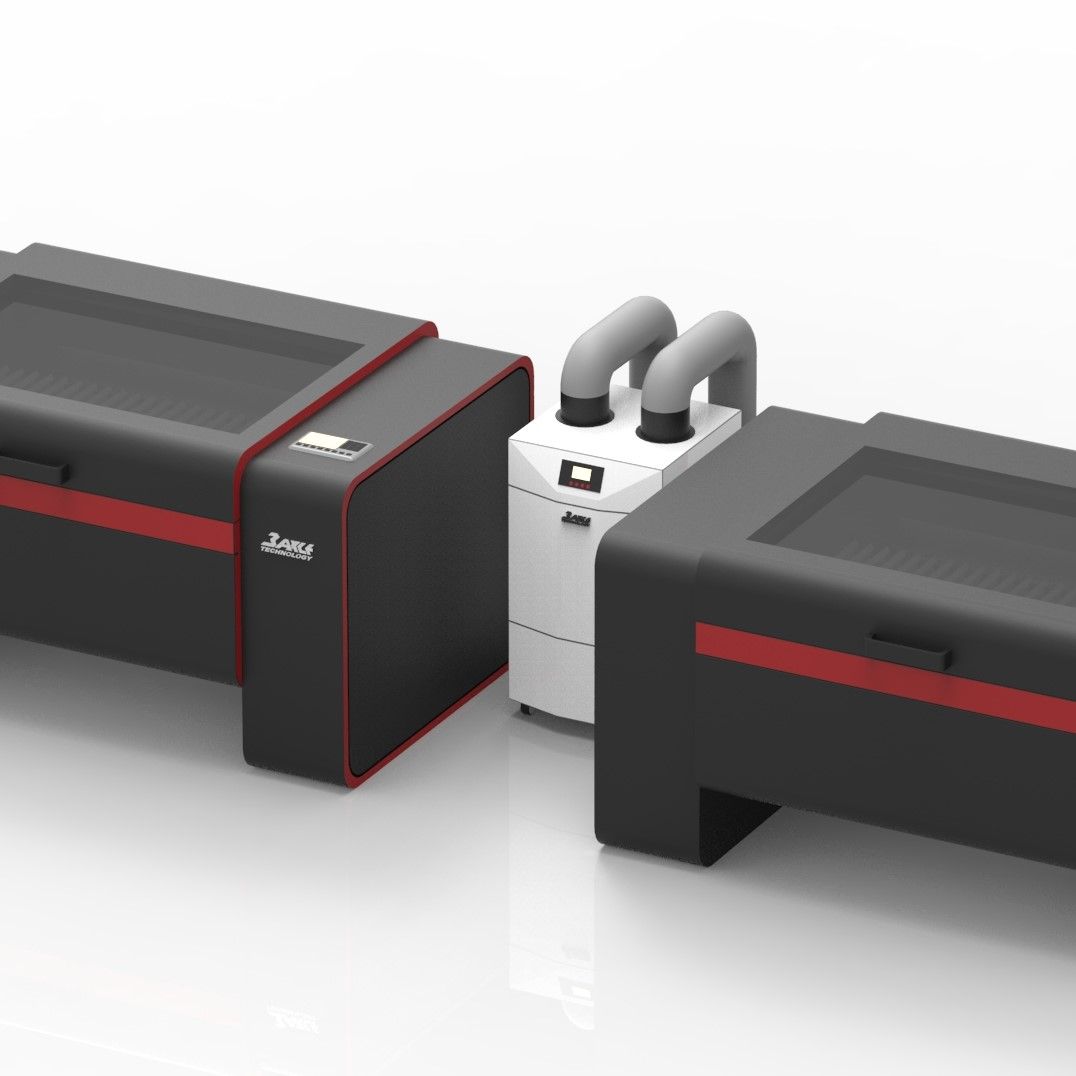

►Air volume up to 1600m3/h

►Equipment special sound-absorbing material reduces operating noise and realizes low noise and high efficiency work.

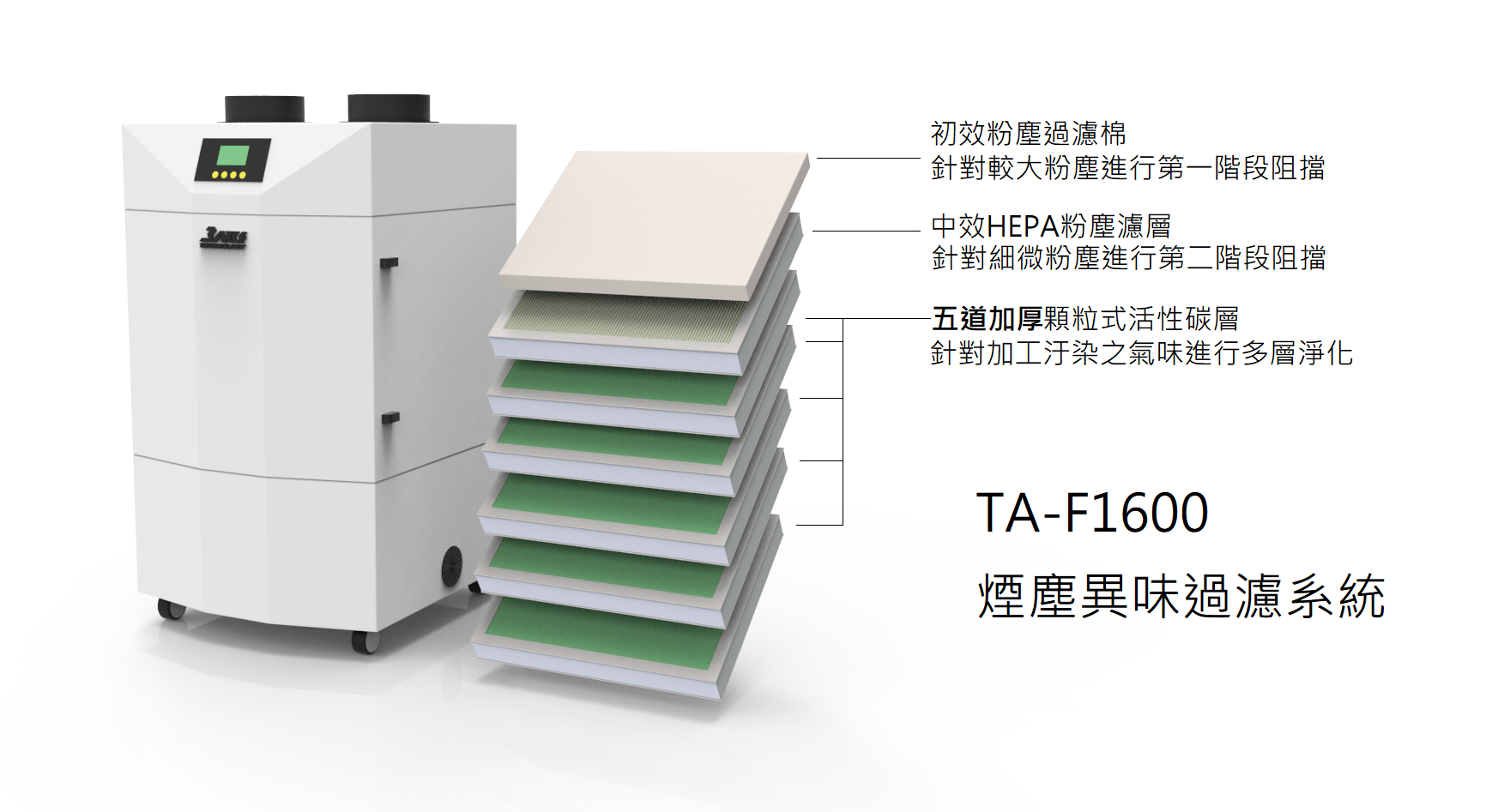

►Up to 7 layers of high-efficiency filter elements, strictly filter all kinds of smoke, dust and irritating and harmful gases to ensure the safety of the indoor environment.

►Mobile integrated chassis design, small footprint, convenient installation, and reduced indoor energy consumption.

►Replacement cycle: under normal conditions

@In the case of more dust: It is recommended to replace it in about 1~2 months. The clogging of the filter will affect the suction power of the soot filter.

@In the case of a small amount of dust and a lot of smoke: It is recommended to replace it in about 3~4 months to effectively reduce the pollution of the odor to the indoor environment.

(This data is for reference only, not as a promised service life, customers need to replace it according to actual usage)

►Average purification efficiency: Due to the structure of the laser equipment, the different settings of laser processing materials and operating parameters have a certain impact on the purification efficiency of smoke and dust.

►Filter service life: The service life of the filter is affected by the following factors, which may vary greatly.

1. Laser processing material

2. Working hours of laser equipment

3. Laser processing power

4. Laser processing site environment