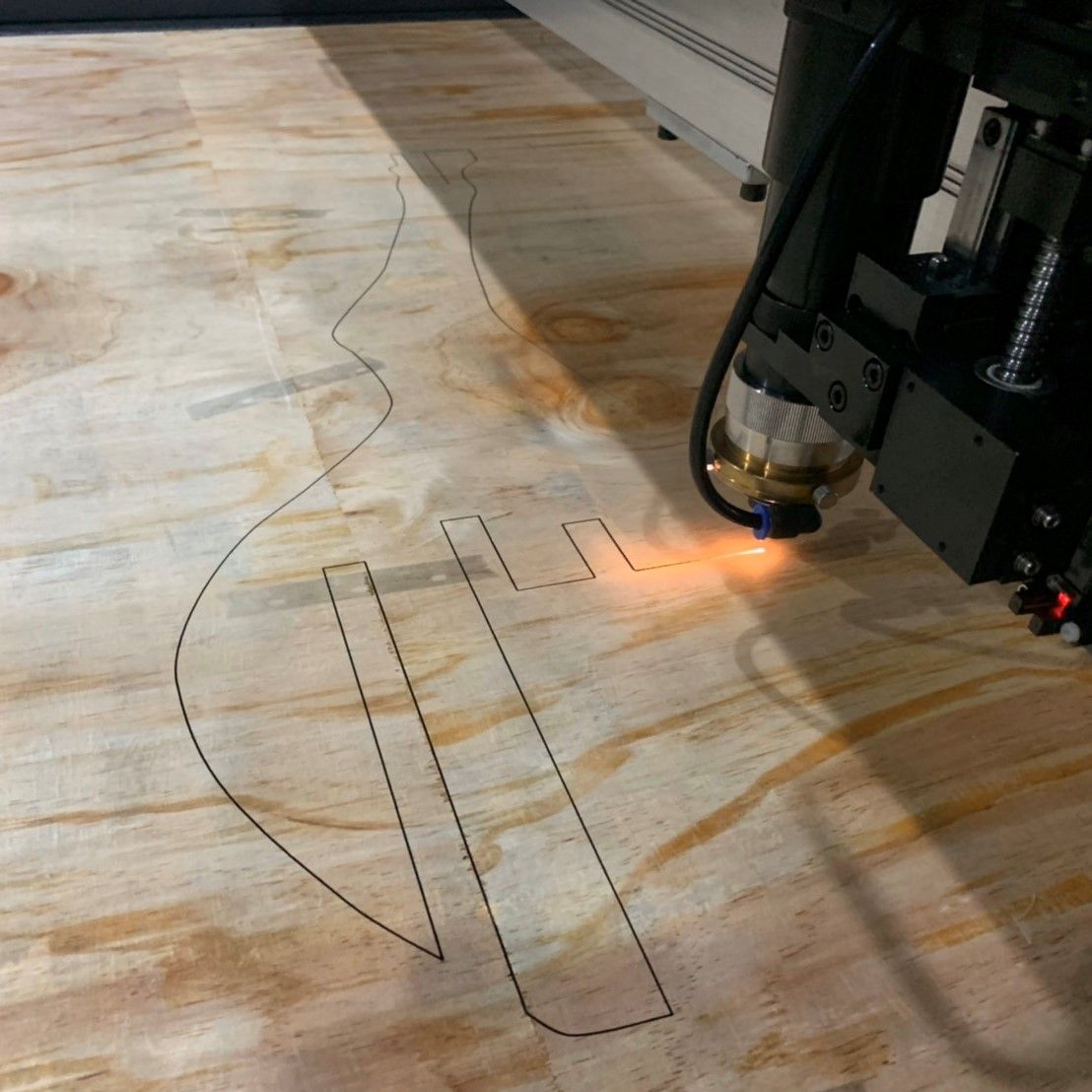

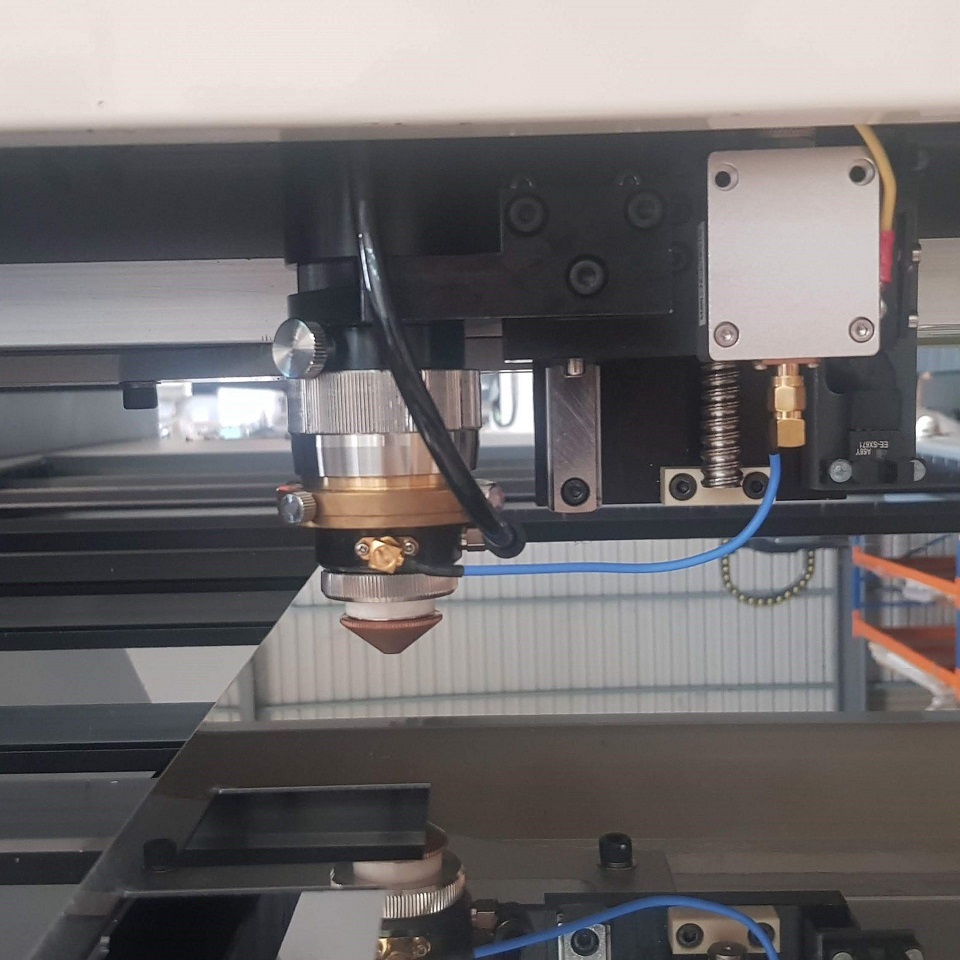

• High precision: XYZ adopts high-precision imported ball screw drive, which greatly improves the speed and cutting accuracy of the equipment and prolongs the life of the machine.

• Servo motor and drive: adopt Japan Mitsubishi servo motor and supporting drive, with long life, high precision and strong stability.

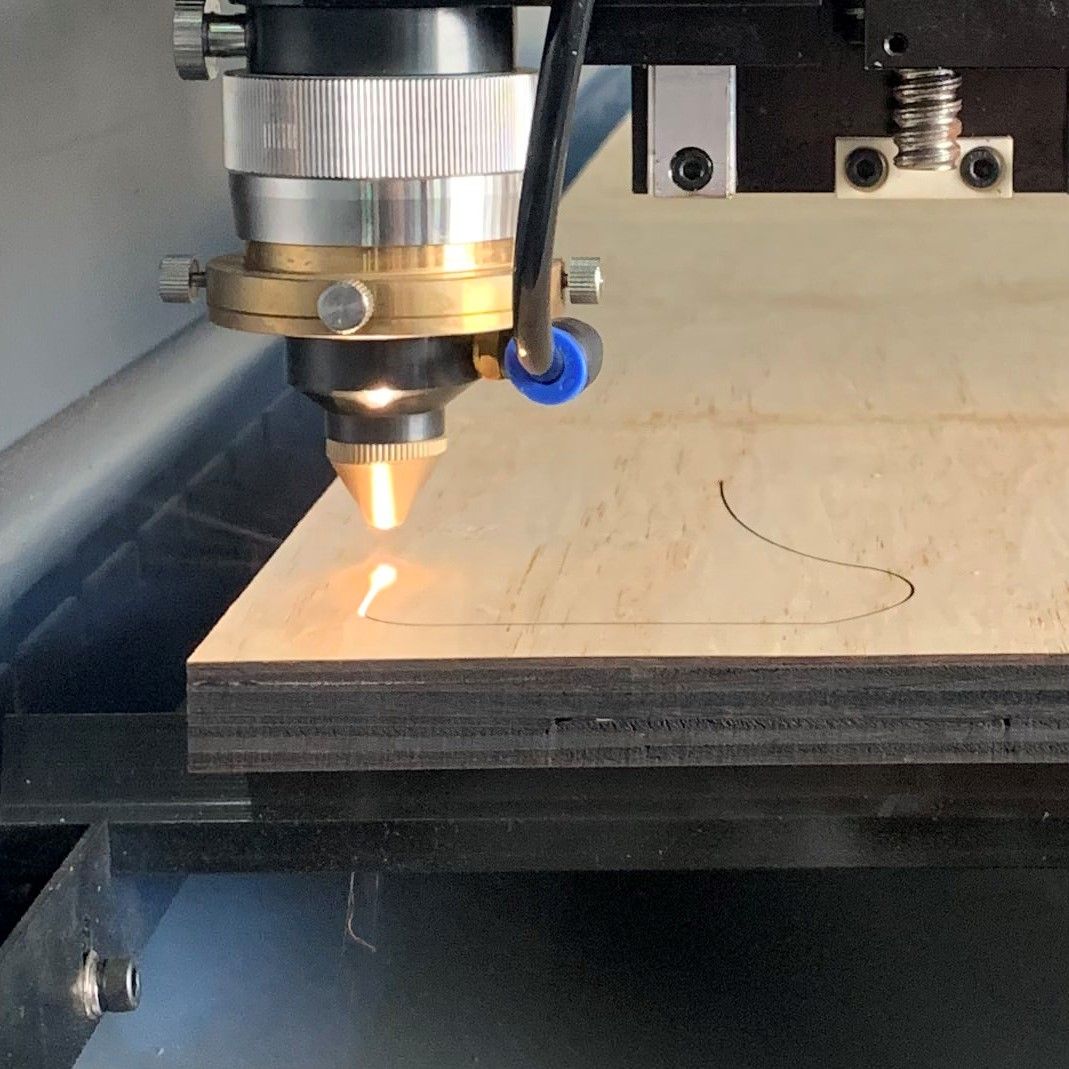

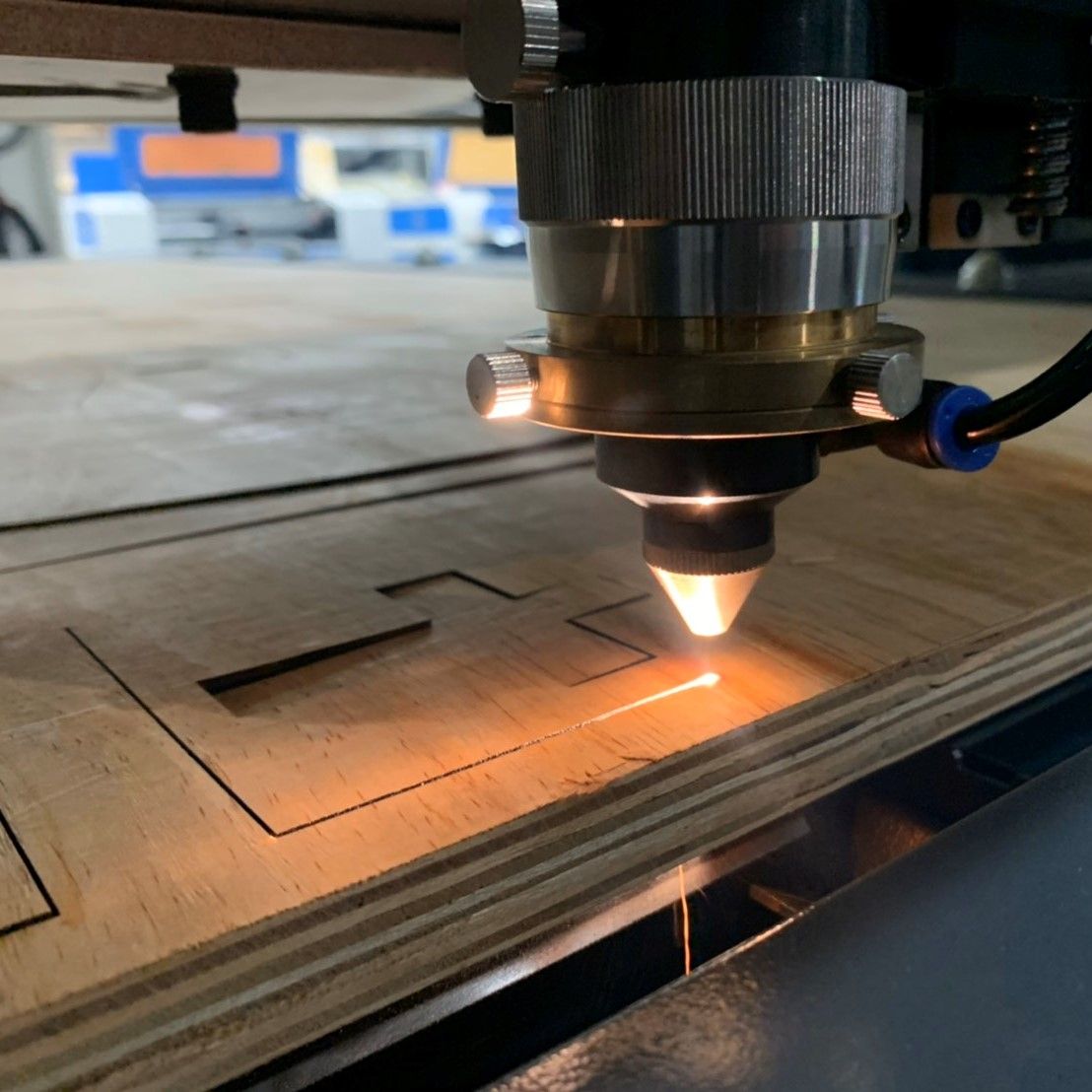

• Special follow-up focusing system for fiber-grade metal: Sensing the uneven surface of the metal sheet and automatically adjusting the focus to ensure the best cutting results.

• Application range

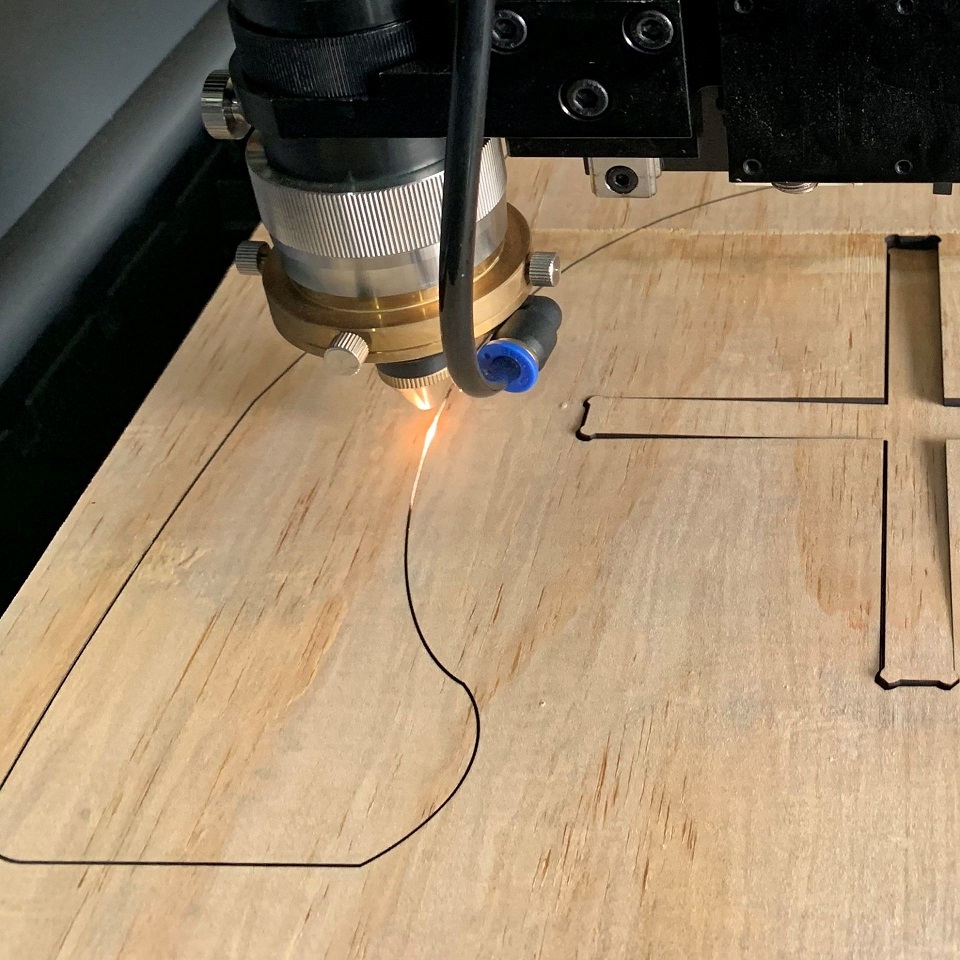

Widely used in metal cutting industries such as models, craft gifts, advertising, decoration, electronics, industry, clothing leather, printing, automobiles, electronics, machinery, kitchen utensils, etc.

• The exclusive design can fine-tune the laser cutting head to ensure the best effect of different maintenance; the laser head is built-in automatic anti-collision device to effectively protect the laser head; reduce the risk of human failure.

• American metal optical lens, durable, more effective reflection light path.

• Industrial refrigeration water chiller.

• Powerful smoke exhaust device, effectively exhaust smoke.

• Mixed cutting special color touch control panel, spare USB and network cable sockets, support DXF, PLT, AI and other file formats.

• Applicable material

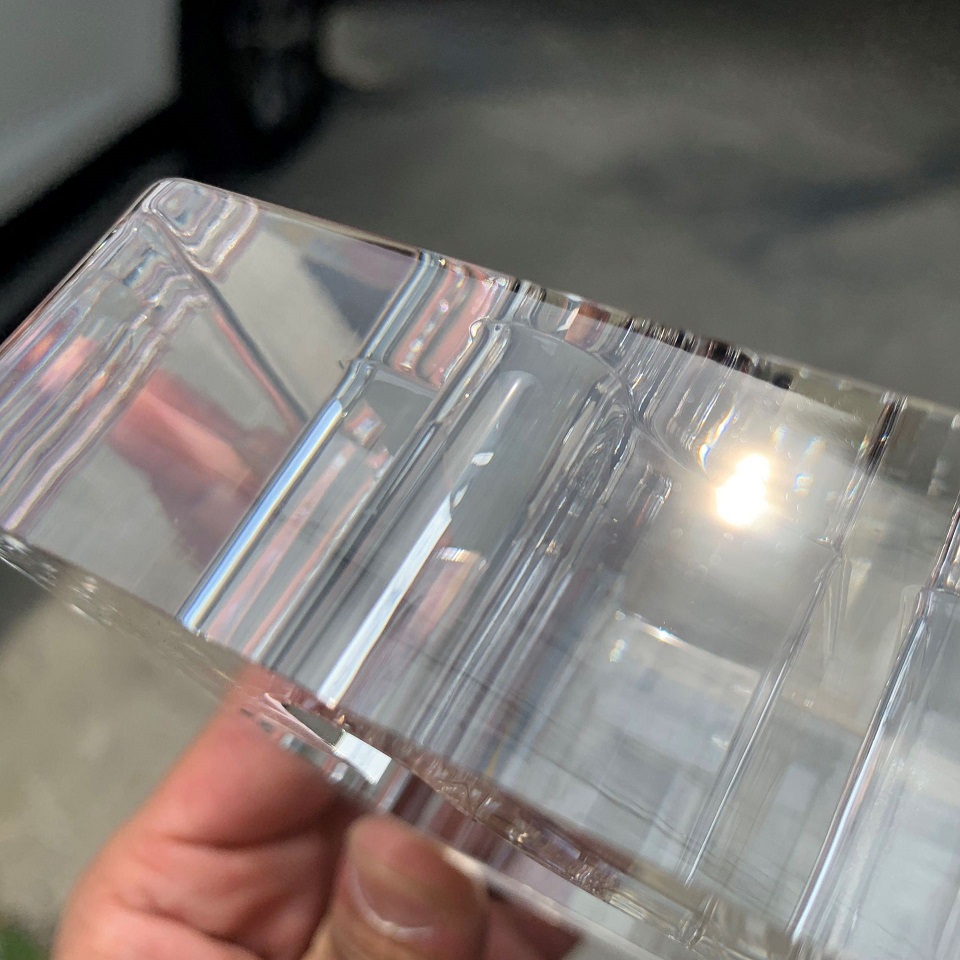

Acrylic (plexiglass), organic board, two-color board, wood board, bamboo products, paper, cloth, leather, ABS, plastic, PVC board, density board, stainless steel, carbon steel, galvanized board and other materials.

![[金屬&非金屬]320W雷射切割機[co2雷射]](/archive/product/item/混切機/TADH-1325-2.png)