Feature of product

Hand-held laser welding machines can be widely used in small hardware welding, stainless steel furniture, cabinets and tableware, ovens, elevators, shelves, stainless steel doors and windows railings, electric boxes and other industries.

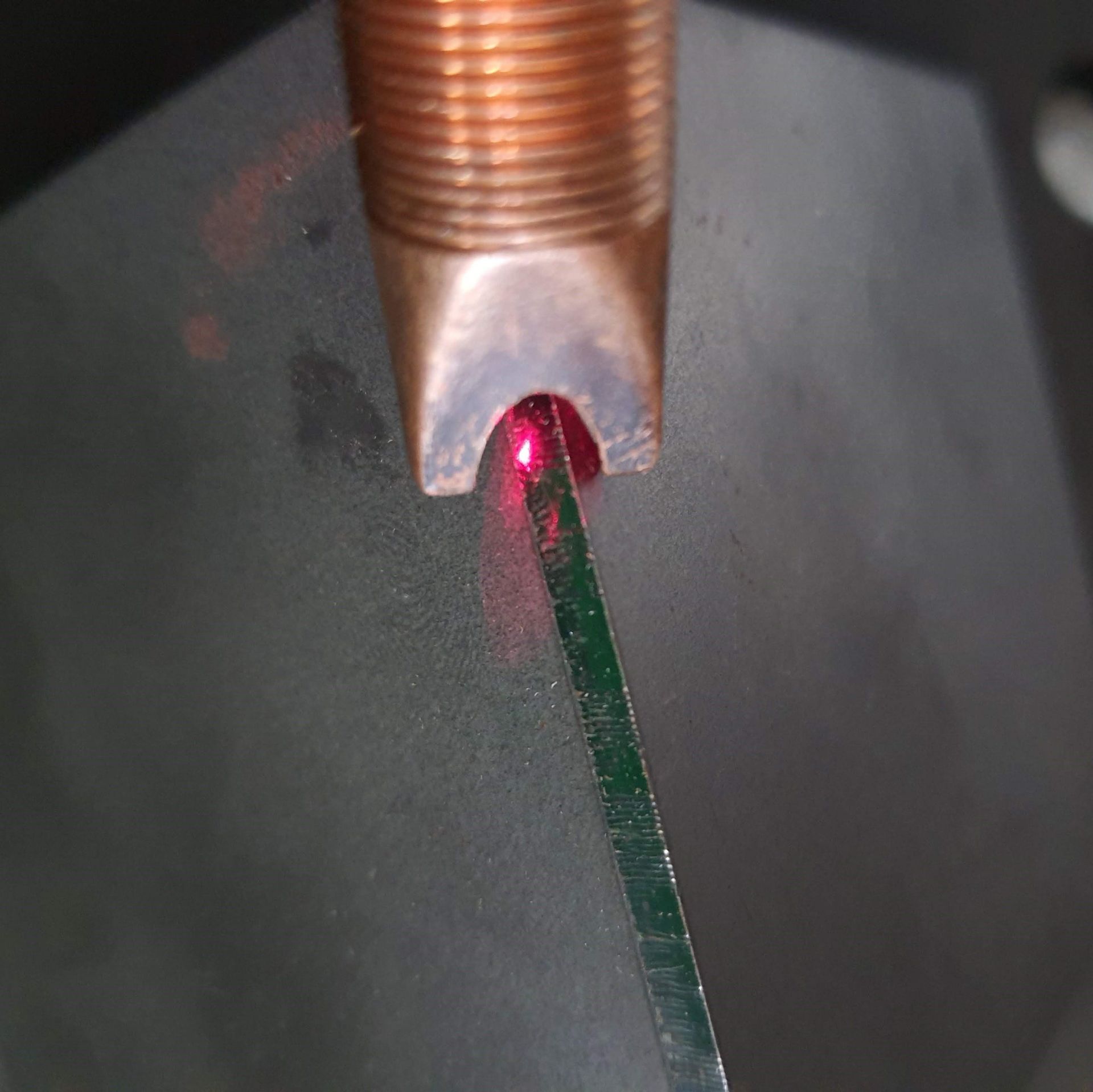

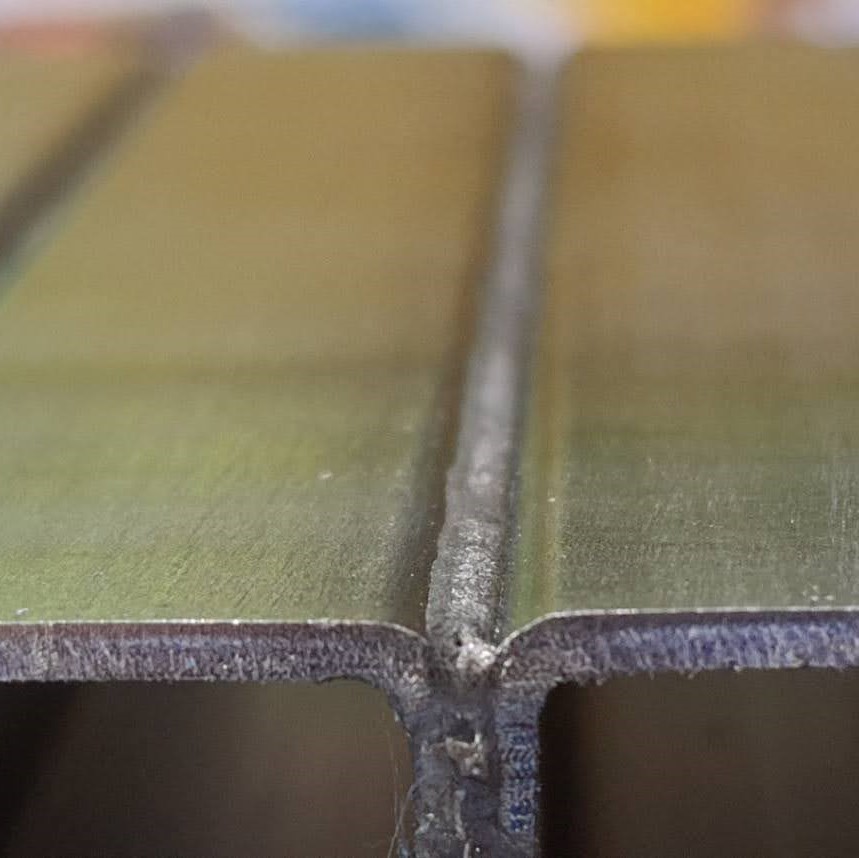

Laser welding is mainly aimed at the welding and cutting of metal sheets within 3MM, which makes up for the large heat melting, easy deformation and post-processing troubles of traditional argon arc welding technology for thin sheet welding.

Hand-held optical fiber laser cutting function for local processing of formed objects, or rapid cutting and modification of objects, without the need to use a professional cutting machine

Four laser welding modes can be adjusted according to different welding requirements.

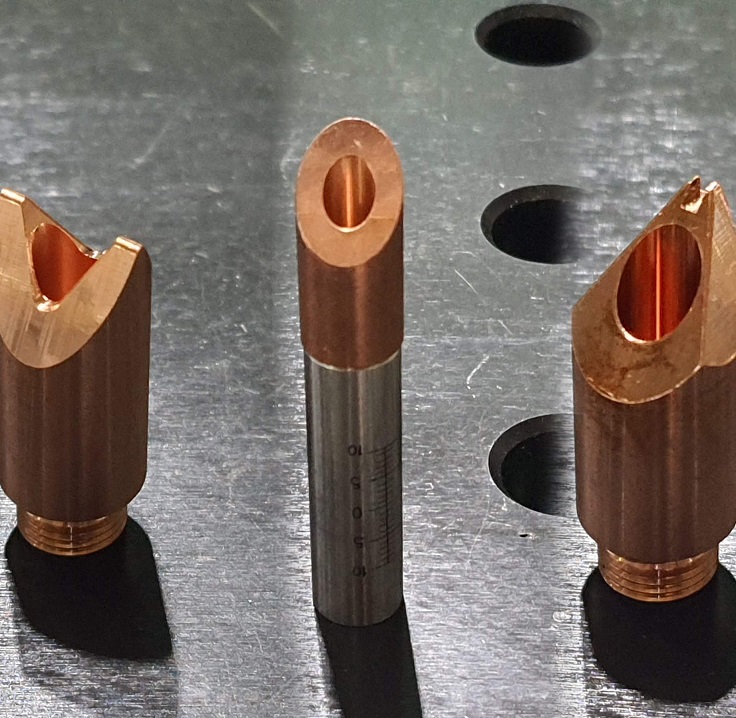

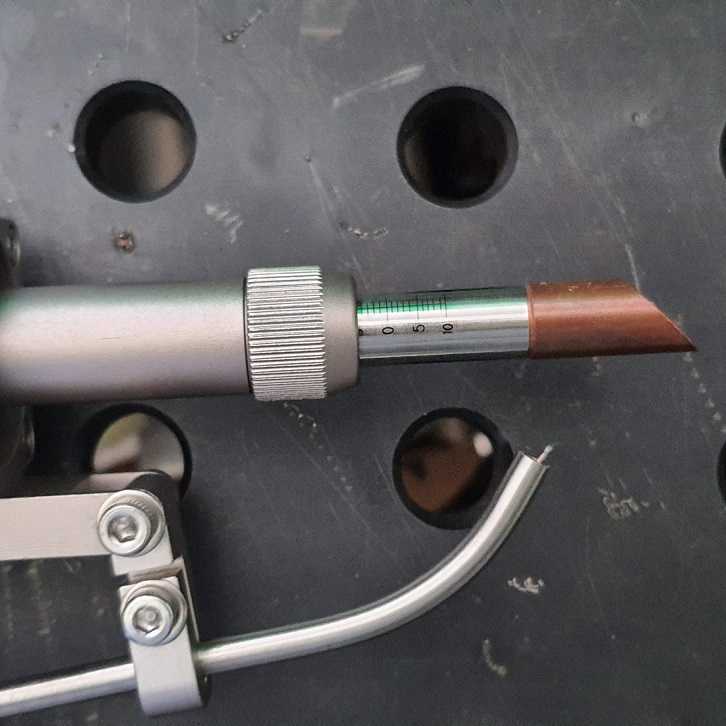

It can be used for cutting quickly by changing the laser sleeve. It is a multi-purpose compound machine.

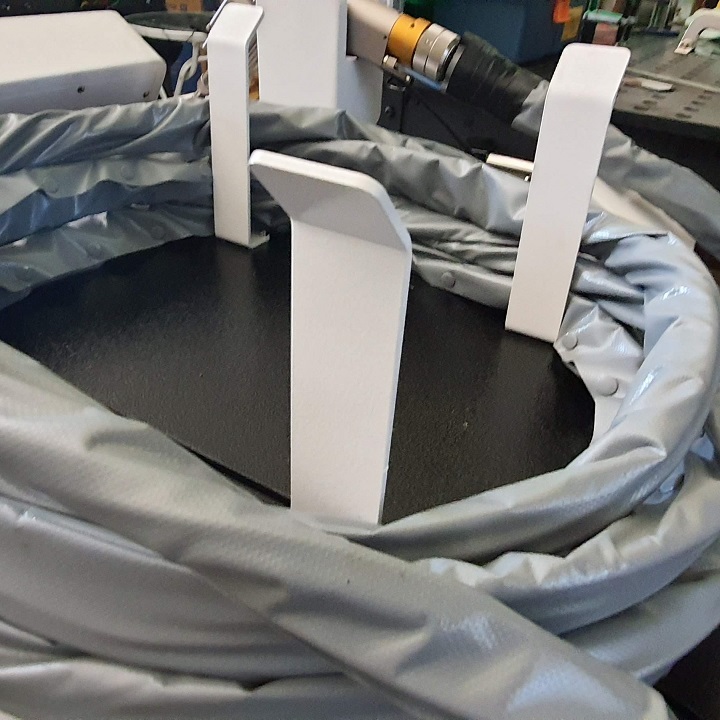

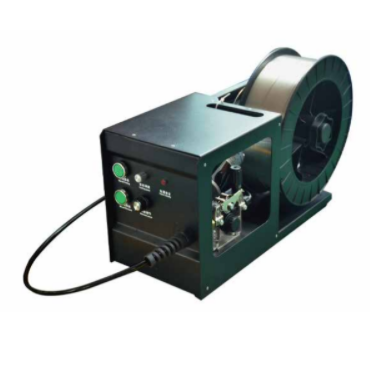

The integrated design of the whole machine adopts a built-in water cooler and 220V voltage access, which is more convenient to move and connect to electricity.

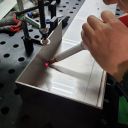

Get started quickly

For users who are experienced in welding or are in contact for the first time, they can quickly learn to operate, saving you expensive technical labor costs!

At present, the wages of technical personnel have increased exponentially; and the operation of laser welding is simple and convenient. Both raw and skilled hands can operate on the machine, which solves the problem of difficult to find technical personnel.

The handheld fiber continuous laser welding machine is a laser welding machine that uses a fiber laser generator as the light source.

Fiber laser is a newly developed fiber laser in the world. It outputs high-energy-density laser beam and gathers it on the surface of the workpiece, so that the area irradiated by the spot on the workpiece is melted and vaporized instantly, and the spot is moved by the handheld head. Laser welding by irradiating the position has obvious advantages compared with bulky gas lasers and solid lasers, and has gradually developed into the preferred laser source in the field of high-precision laser processing.

Laser welding is the best welding method among the various welding technologies that people have mastered today. The advantages of laser welding are: small thermal distortion, high welding accuracy, low noise, no pollution, and easy to realize automatic welding. Laser welding is An advanced manufacturing technology that has the advantages of wide application range, flexible process, high processing accuracy, good quality, clean production process, and easy realization of automation, flexibility, intelligence, and improvement of product quality and labor productivity.